One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

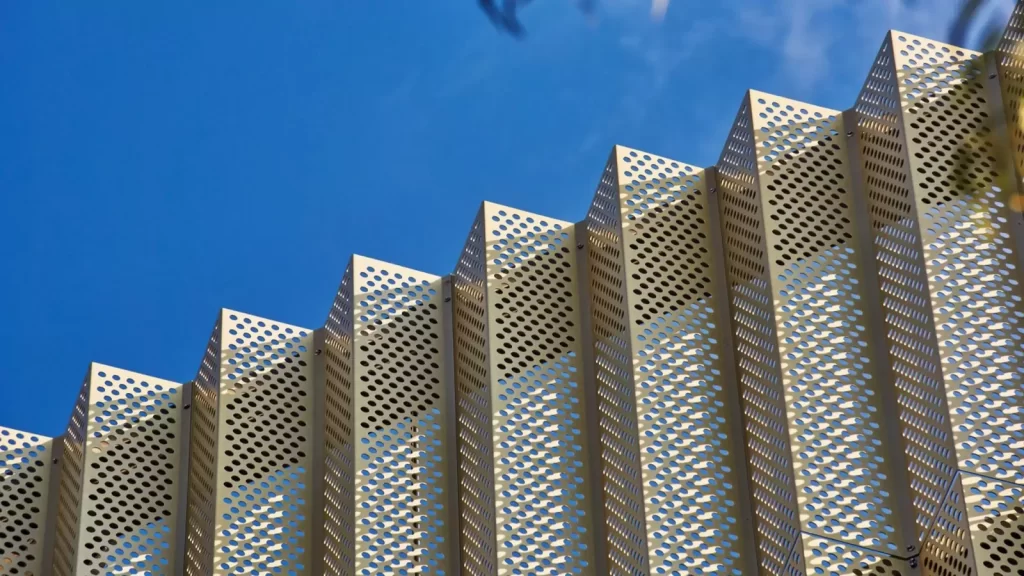

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

A concealed clip system with 6063 – T5 aluminum brackets is recommended:

– Bracket spacing: ≤600mm vertically and horizontally for 3mm panels

– Expansion gap: Allow 8 – 10mm between panels (temperature range dependent)

– Fastener specs: A2/A4 stainless steel self – drilling screws (M6×25mm)

Testing standard: Compliance with ASTM E330 wind load requirements up to 3,500Pa.

Follow this maintenance protocol:

1. Frequency: Biannual cleaning for urban areas, annual for rural

2. Solution: pH – neutral cleaner diluted to 5% concentration

3. Method: Soft nylon brush (≤500GSM pressure) with rinse within 15 minutes

Prohibited: Abrasive pads, high – pressure washers (>800psi), or alkaline solutions (pH >9).

Three – axis CNC bending achieves radii down to 150mm without cracking:

– Material grade: 5052 – H32 preferred for cold bending (minimum 0.8T R/T ratio)

– Grain direction: Bend perpendicular to rolling direction

– Post – treatment: Stress – relief annealing at 200°C for 30 mins after forming

Thickness varies by material: aluminum panels typically range from 0.5mm to

3mm, while steel panels may be thicker (1mm to 6mm) for structural needs.

Installation methods include direct fastening to substructures or using

adhesive mounts. Professional tools like leveling systems ensure alignment

and durability.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.