One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Advantage

A PVDF coating technology ensures that rainwater naturally cleans the surface, reducing the need for frequent maintenance and minimizing risks associated with high-altitude cleaning.

Advantage

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Aluminium wall cladding primarily uses fluorocarbon spray coating (PVDF), powder coating, and anodized finishes.

– Fluorocarbon coating offers superior UV resistance (25+ years), ideal for coastal/high – pollution areas.

– Powder coating provides cost – effective color customization (200+ RAL options) for indoor/urban projects.

– Anodized finishes deliver metallic aesthetics with scratch resistance, best for architectural accents.

Key factors: Prioritize PVDF for extreme weather; verify coating thickness (≥40μm for PVDF, ≥60μm for powder).

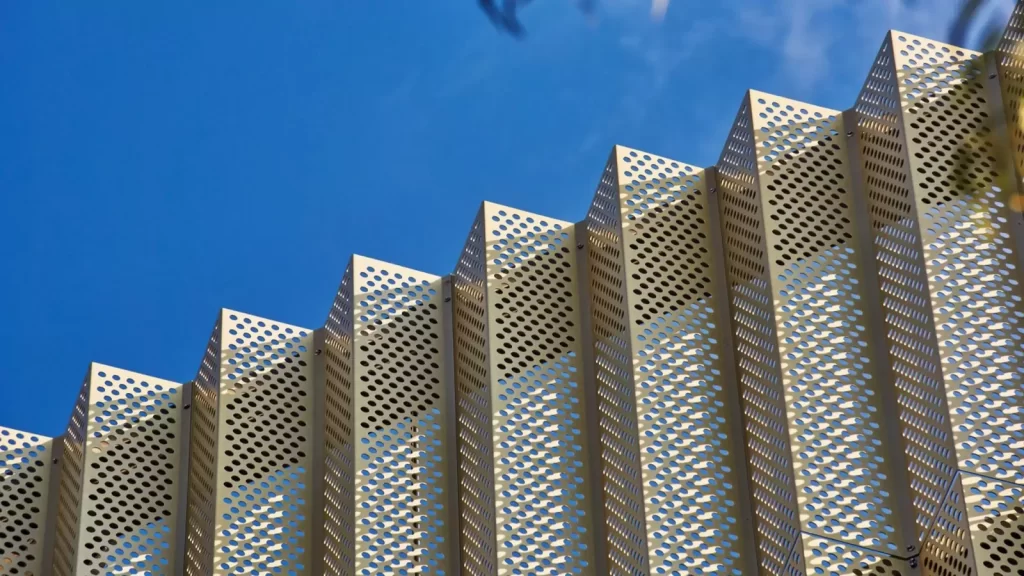

Perforation designs depend on aperture size (3 – 20mm), open area ratio (15% – 70%), and pattern geometry.

– Acoustic panels: 20% – 40% open area with micro – perforations (3 – 5mm) for sound absorption.

– Ventilation façades: Use 50% – 70% open area with staggered layouts.

Critical steps:

1. Confirm load – bearing capacity via FEM analysis.

2. Avoid sharp corners to prevent material fatigue.

3. Pair with backing membranes for waterproofing.

Standard tolerances follow EN 485 – 2:

– Flatness: ≤0.3% of panel length.

– Bend radius: Minimum 1.5x material thickness (e.g., 3mm for 2mm sheets).

– Angular deviation: ±1° for single bends, ±2° for complex forms.

Critical checks:

– Verify alloy temper (H24 recommended for 90°+ bends).

– Use CNC press brakes with ±0.1mm repeatability.

– Post – forming anodizing requires stress – relief pretreatment.

We enforce the GB/T 9286 color difference control standard, ensuring ΔE≤1.5 (visually no color difference). We offer a triple

confirmation mechanism using Pantone color cards, RAL color systems, and physical samples, supporting sample retention.

Minimum order quantity is 20㎡ (special processes start at 50㎡), with regular orders delivered within 15 working days. Complex

process orders do not exceed 25 working days (including a 7-day curing period).

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.