One-stop Solution for Residential & Commercial Building

Decoration Projects

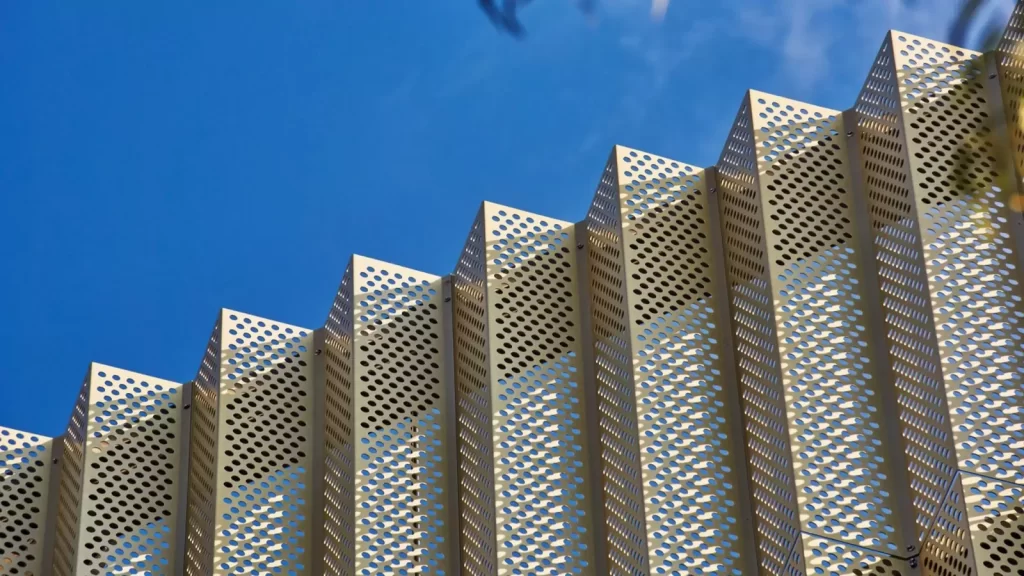

Perforated Metal Panel Facade is a versatile architectural cladding solution designed for modern building exteriors. Its precision – punched patterns enhance ventilation and natural light diffusion while maintaining structural durability. Ideal for commercial complexes, cultural centers, and urban infrastructure, the panels combine weather resistance with customizable designs to achieve dynamic visual effects. Engineered for easy installation and low maintenance.

Advantage

Advantage

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Fluorocarbon Coating (PVDF) and powder coating are optimal for perforated aluminum facades.

1. Calculate open area ratio (15%-60%) based on solar shading coefficient requirements (ASHRAE 90.1);

2. Select hole diameter (2-12mm) matching structural spans (≤1.2m panel width recommended);

3. Verify punching Mould tolerance: ±0.1mm for pattern consistency (GB/T 1804 – m).

1. Maintain minimum bend radius = 1.5× material thickness (Aluminum Association Standard);

2. Orient punching pattern parallel to bending axis;

3. Pre – anneal H32 temper sheets before forming complex curves.

We adopt a five-stage standardized process: Concept sketch → 3D modeling (supporting Rhino/SolidWorks formats) → mechanical

simulation → sample prototyping → batch production.

The precision of aluminum plate processing services typically achieves ±0.1mm to ±0.5mm accuracy depending on the technique

used (e.g., laser cutting, CNC machining). Advanced equipment ensures tight tolerances suitable for architectural and industrial

applications.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.