One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

A PVDF coating technology ensures that rainwater naturally cleans the surface, reducing the need for frequent maintenance and minimizing risks associated with high-altitude cleaning.

Advantage

Rigorously tested to withstand 12-level typhoon simulations, the panels feature a secure edge-locking design to ensure stability in high-wind areas.

Advantage

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

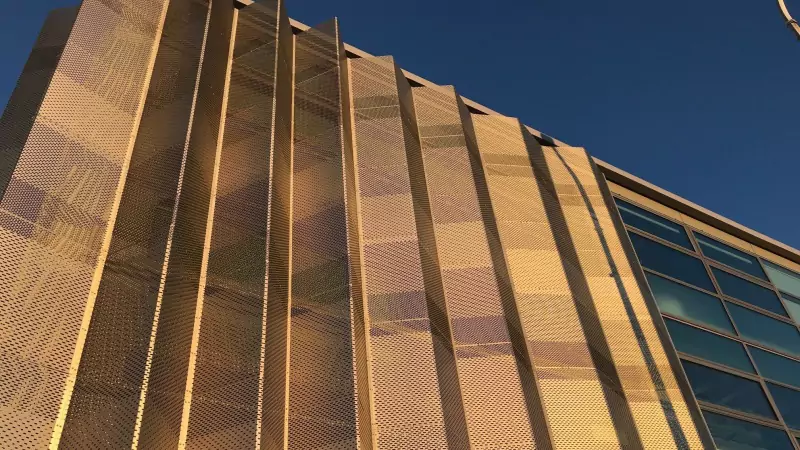

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Step – by – Step Solution:

1. Material Prep: Use 3003 – H24/H14 aluminum (8% – 12% elongation rate) instead of 1100 series.

2. Tool Setup: Maintain 4x material thickness as minimum bending radius (e.g., 3mm sheet → 12mm radius).

3. Stress Relief: Apply V – grooving to 2/3 material depth before bending for 3mm+ thick panels.

Critical Note: Avoid cold bending after anodizing – perform forming before surface treatment.

Technical Guidance:

– Safe Open Area: ≤30% for 3mm panels (40% max with 2.5mm min residual thickness).

– Pattern Design: Hexagonal holes provide 18% higher stiffness vs. circular holes at equal open rates.

– Load Test: Panels must pass 1.5kPa wind load test per EN 13830 after perforation.

Case Example: 2.5mm 5052 – H32 with 6mm round holes at 15mm spacing (22% open) achieved 2.8kPa tested capacity.

1. Batch Control: Use aluminum coils from same melt batch (verify alloy certificate: Cu≤0.1%, Fe≤0.7%).

2. Spray Parameters: Maintain 70%±5% booth humidity with 23°C±2°C temperature during coating.

3. Color Matching: Spectrophotometer tolerance ΔE≤1.0 NBS under D65 light source.

Field Fix: For installed panels with ΔE>2.0, apply matching PVDF touch – up paint (85% opacity) with 200μm overlap.

We provide a 6063-T5 aluminum alloy keel system (load-bearing capacity ≥200kg/m²), with a matching hanging system that has

passed a 500,000-cycle fatigue test. Keel systems can be selected based on the installation method.

We provide four-layer protective packaging: PE film + bubble wrap + custom wooden pallets + corner protection sleeves, controlling

damage rates to within 0.3%.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.