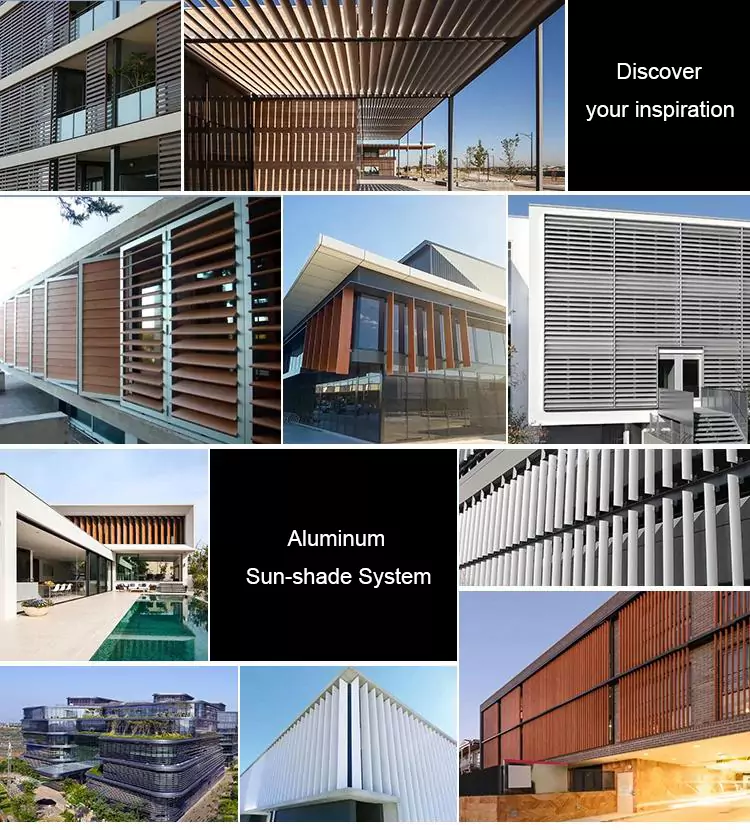

One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Advantage

The lightweight nature of aluminum and the pre – fabricated components make the installation process quick and simple. This minimizes construction time and labor costs, allowing projects to be completed more efficiently.

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

1. Material Selection: Use 5052 – H32 alloy with 2.5 – 4mm thickness for spans exceeding 3m.

2. Reinforcement Design: Integrate 15mm folded edges on longitudinal sides (per EN 14024).

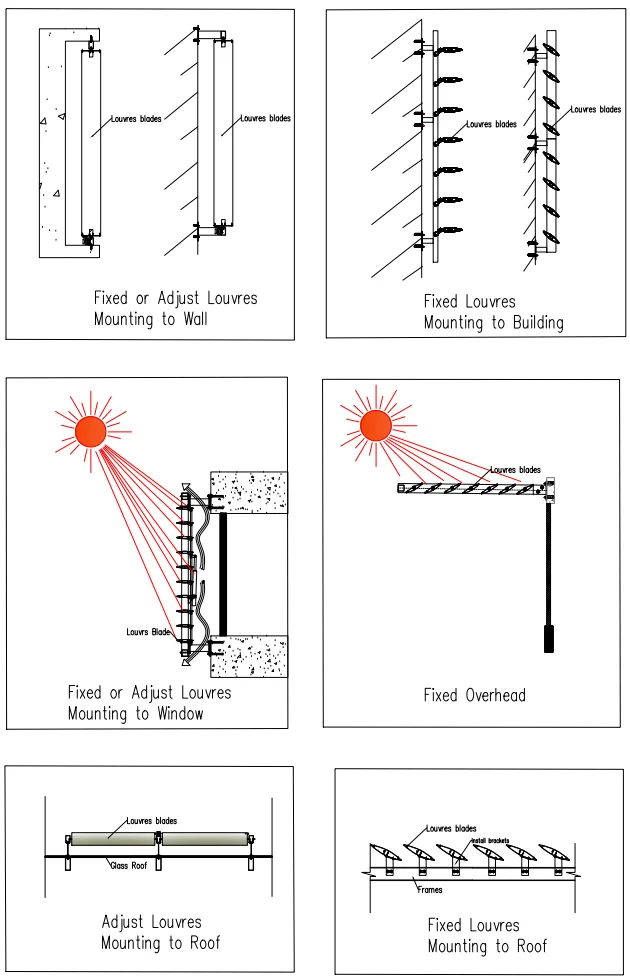

3. Mounting: Install 600mm spaced stainless steel brackets (AISI 316) with thermal break pads.

Critical Data: Deflection must stay below L/200 (e.g., ≤15mm for 3m span) per AS/NZS 4284.

| Pattern | Open Area % | Solar Blocking Efficiency |

|———|————-|—————————|

| Hexagon | 35 – 40% | 62% (ASHRAE 90.1 standard) |

| Linear | 25 – 30% | 55% |

| Round | 45 – 50% | 48% |

Design Advice: Combine 40% hexagonal perforation with 30° tilt angle for tropical climates.

1. Drainage: Add 5mm weep holes every 800mm along lower edges (compliant with BS EN 12179).

2. Airflow: Maintain 20mm minimum gap between louver blades for moisture evaporation.

3. Coating: Apply hydrophobic nano – coating (contact angle >110°) on concealed surfaces.

Pro Tip: Use thermal imaging during commissioning to identify cold bridges.

The precision of aluminum plate processing services typically achieves ±0.1mm to ±0.5mm accuracy depending on the technique

used (e.g., laser cutting, CNC machining). Advanced equipment ensures tight tolerances suitable for architectural and industrial

applications.

We enforce the GB/T 9286 color difference control standard, ensuring ΔE≤1.5 (visually no color difference). We offer a triple

confirmation mechanism using Pantone color cards, RAL color systems, and physical samples, supporting sample retention.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.