One-stop Solution for Residential & Commercial Building

Decoration Projects

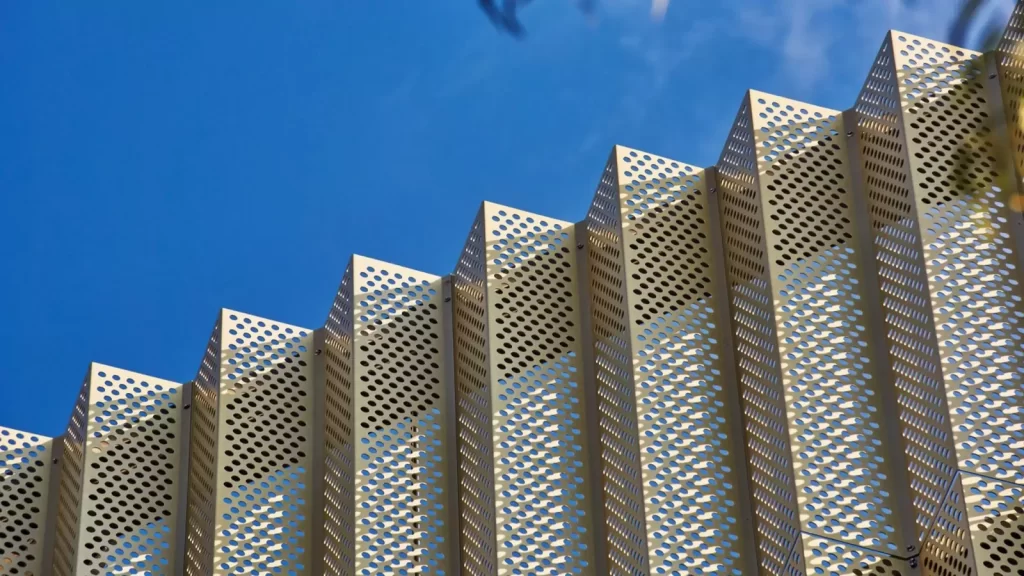

Perforated metal facade systems are engineered for dynamic architectural exteriors, combining aesthetics with structural resilience. Made from high-strength steel or aluminum alloys, these panels offer corrosion resistance, UV stability, and weatherproof durability. Customizable perforation patterns optimize daylight control, airflow, and energy efficiency while maintaining privacy. Lightweight yet robust, they suit sunshades, cladding, and decorative screens. Fire-rated, low-maintenance, and acoustically optimized for noise reduction, these panels meet stringent building codes for commercial, institutional, and civic projects. Enhance sustainability and curb appeal with adaptable designs that balance form, function, and long-term performance.

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Advantage

Advantage

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Best For:

– Architectural cladding requiring breathability and visual appeal.

– Industrial screens needing debris filtration or equipment cooling.

For project-specific benefits like lightweight installation (30–50% lighter than steel) or sustainability (100% recyclable), request a consultation.

Perforated metal panels may face debris accumulation, reduced structural strength, and higher fabrication costs compared to solid sheets.

Key Considerations:

– Maintenance: Small holes trap dust and pollutants, requiring frequent cleaning to maintain airflow and appearance.

– Load Capacity: Excessive perforations (over 30% open area) weaken structural integrity, limiting use in high-stress applications like load-bearing façades.

– Cost Complexity: Intricate patterns or custom hole designs increase material waste and CNC machining time, raising project costs.

Scenario Recommendations:

– Avoid perforated panels in high-pollution areas unless paired with anti-clog coatings.

– For structural projects, opt for thicker aluminum (≥3mm) and ≤20% open area to balance aesthetics and strength.

Discuss design optimization with our team to mitigate these drawbacks while leveraging perforated aluminum benefits.

A perforated metal panel is a precision-punched sheet (typically aluminum) with uniform holes arranged in custom patterns, designed for architectural cladding, industrial filtration, or acoustic control.

Key Features:

– Material: Made from durable aluminum sheets (0.5–6mm thickness) for corrosion resistance and lightweight installation.

– Fabrication: Created via CNC punching or laser cutting, ensuring ±0.2mm accuracy for complex designs (e.g., round, slotted, decorative shapes).

– Functionality: Balances airflow optimization (10–60% open area) with structural integrity, ideal for façade ventilation or machinery guards.

Common Uses:

– Architectural: Sunshades, decorative screens, or ceiling panels.

– Industrial: Equipment shielding, dust filters, or soundproofing barriers.

For project-specific patterns or load-bearing requirements, consult our team to optimize hole size, spacing, and material grade.

All of our aluminum plate products strictly adhere to the national standard GB/T 23443-2009 “Aluminum Single Panels for Architectural Decoration”, ensuring key performance indicators such as tensile strength ≥150MPa and coating thickness ≥25μm meet the requirements.

We enforce the GB/T 9286 color difference control standard, ensuring ΔE≤1.5 (visually no color difference). We offer a triple confirmation mechanism using Pantone color cards, RAL color systems, and physical samples, supporting sample retention.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.