One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

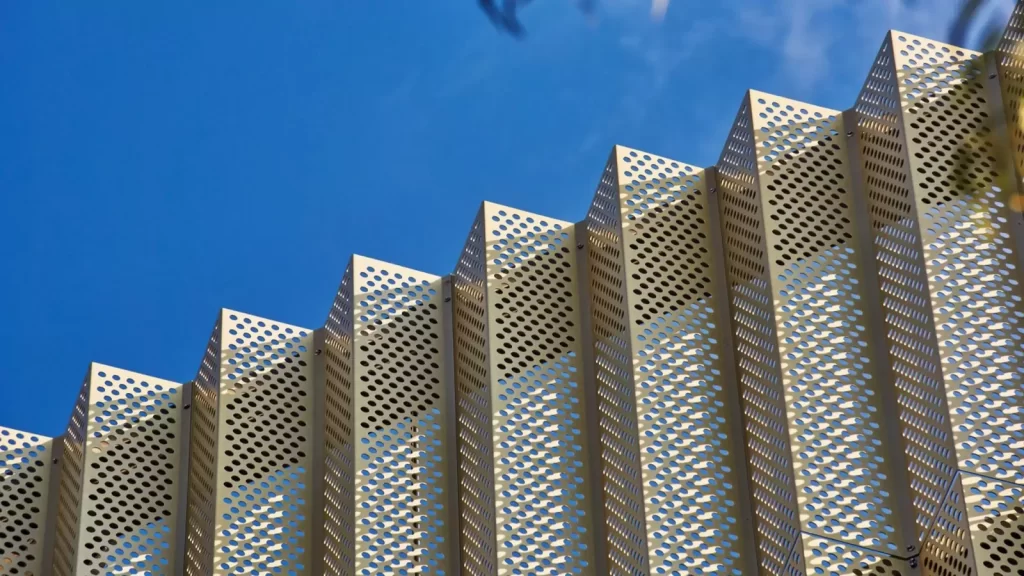

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Advantage

Advantage

A PVDF coating technology ensures that rainwater naturally cleans the surface, reducing the need for frequent maintenance and minimizing risks associated with high-altitude cleaning.

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Fluorocarbon coating (PVDF) is optimal for coastal applications. This treatment provides:

– Superior corrosion resistance (withstands 15+ years in salt spray tests)

– UV stability (90% gloss retention after 10 years)

– Self-cleaning properties (25° contact angle for water runoff)

Alternative: Anodized finishes offer good durability but require frequent maintenance in high – salinity zones.

Recommendation: Specify 30μm minimum PVDF coating thickness for seaside projects.

Follow this 3-step maintenance protocol:

1. Quarterly cleaning: Use pH-neutral detergent + soft sponge

2. Inspection: Check for chips >2mm diameter requiring touch-up

3. Damage repair: Apply matching RAL-color epoxy within 48hrs of exposure

Critical Note: Avoid abrasive cleaners (>1000 grit equivalent) to preserve 60 – 80μm coating integrity. Industrial areas may require biannual maintenance cycles.

Thickness selection matrix:

| Building Height | Recommended Thickness | Fixing System |

|——————|———————–|—————|

| ≤30m | 2.5mm | Tab-and-slot |

| 30 – 150m | 3.0 – 4.0mm | Shear clip |

| >150m | 4.0 – 6.0mm | Tension rod |

*Key Factor:* Wind load calculations must confirm deflection <L/240. Always pair thicker gauges with 6063-T6 alloy for structural applications.

The precision of aluminum plate processing services typically achieves ±0.1mm to ±0.5mm accuracy depending on the technique

used (e.g., laser cutting, CNC machining). Advanced equipment ensures tight tolerances suitable for architectural and industrial

applications.

Minimum order quantity is 20㎡ (special processes start at 50㎡), with regular orders delivered within 15 working days. Complex

process orders do not exceed 25 working days (including a 7-day curing period).

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.