One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Advantage

Rigorously tested to withstand 12-level typhoon simulations, the panels feature a secure edge-locking design to ensure stability in high-wind areas.

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

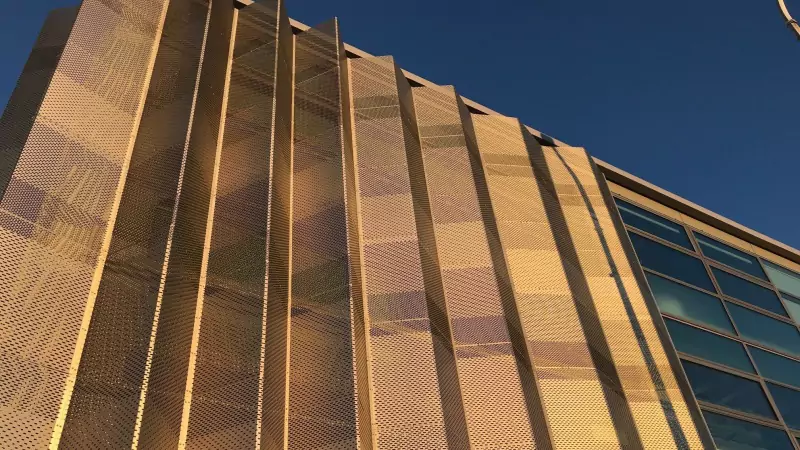

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Precision machining ensures structural integrity while meeting design needs.

1. Punching: ≤30% open area recommended for exterior panels to maintain wind load resistance (ASTM E330 standards).

2. Profiling: Laser-cut geometric patterns require ≥2.5mm thickness to prevent warping.

Key consideration: Always specify hole spacing ≥3x hole diameter to avoid stress concentration.

Step-by-step guidance:

1. Use open-joint systems with 5-8mm gaps for thermal expansion (comply with ASTM C1401).

2. Apply butyl sealant to overlapping seams and concealed fixings.

3. Install 1.5mm-thick EPDM gaskets at panel junctions.

Critical check: Verify drainage channels (≥2% slope) and conduct water spray tests post-installation.

Material specification:

– Basic zones: 2.0-3.0mm AA3003/H24 alloy (wind load ≤2.5 kPa).

– Coastal/high-risk areas: 4.0-6.0mm AA5052/H32 with reinforced brackets (wind load ≥4.0 kPa).

Certification: Panels must pass ASTM B209-14 tensile testing (≥145 MPa yield strength). Always pair with T6-grade aluminum alloy subframes.

The precision of aluminum plate processing services typically achieves ±0.1mm to ±0.5mm accuracy depending on the technique

used (e.g., laser cutting, CNC machining). Advanced equipment ensures tight tolerances suitable for architectural and industrial

applications.

We enforce the GB/T 9286 color difference control standard, ensuring ΔE≤1.5 (visually no color difference). We offer a triple

confirmation mechanism using Pantone color cards, RAL color systems, and physical samples, supporting sample retention.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.