One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Aluminum is strong yet lightweight. This makes the curtain walls easy to handle and install, reducing the need for heavy – duty equipment. They are also suitable for various building structures, including high – rise buildings.

Advantage

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Solution Checklist:

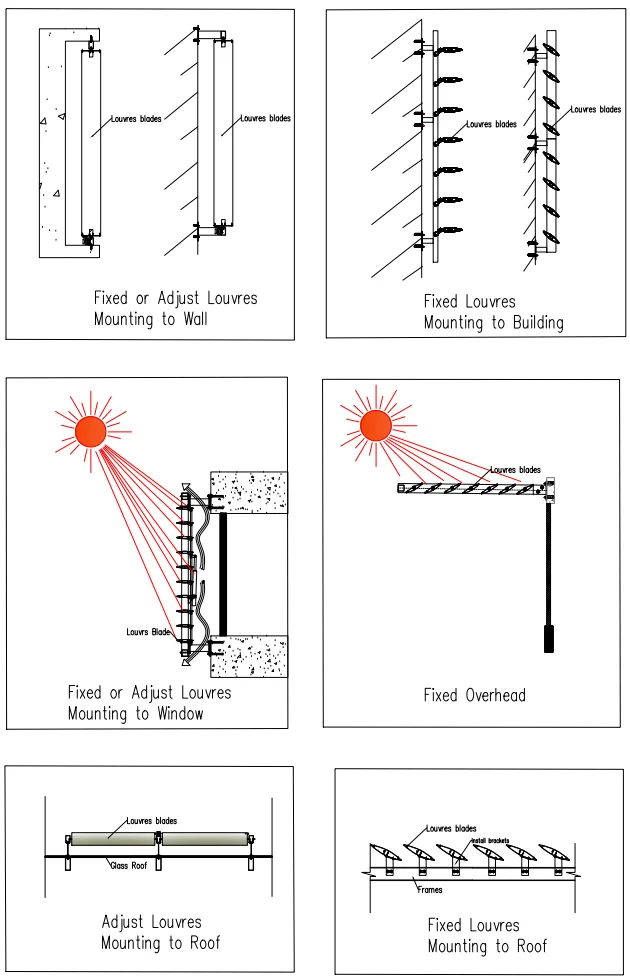

1. Material selection: Use 3xxx/5xxx series alloys (H24 temper) with 2.5 – 3.0mm thickness for spans >3m

2. Structural reinforcement:

– Continuous T – shaped stiffeners (15 – 20% cross – section area)

– Edge hemming depth ≥15mm

3. Installation: Maintain 5 – 8mm thermal expansion gaps between modules

Calculation Method:

1. Orientation factor: Multiply base SHGC (0.25 – 0.35) by azimuth correction factor

2. Spacing ratio: Optimal 1:1 blade depth – to – spacing achieves 60% solar blockage

3. Material reflectivity: Anodized 6063 – T6 (85% reflectivity) reduces SHGC by 15% vs. painted surfaces

Maintenance Matrix:

| Interval | Action | Technical Requirement |

|———-|——–|————————|

| Biannual | Inspection | Check coating adhesion via ASTM D3359 cross – hatch test |

| Annual | Cleaning | pH – neutral cleaner (5 – 8.5) @ ≤40°C water temperature |

| 5 – Year | Refurbishment | Localized PVDF recoating with 50μm DFT minimum |

Failure Alert: Chalking level ≥8 (ASTM D4214) indicates immediate recoating need.

Our products undergo rigorous testing, including fatigue cycles, wind pressure simulations, and

coating adhesion checks, to ensure long-term performance.

We partner with reliable freight forwarders to offer sea, air, and land transport options, tailored to

your timeline and budget.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.