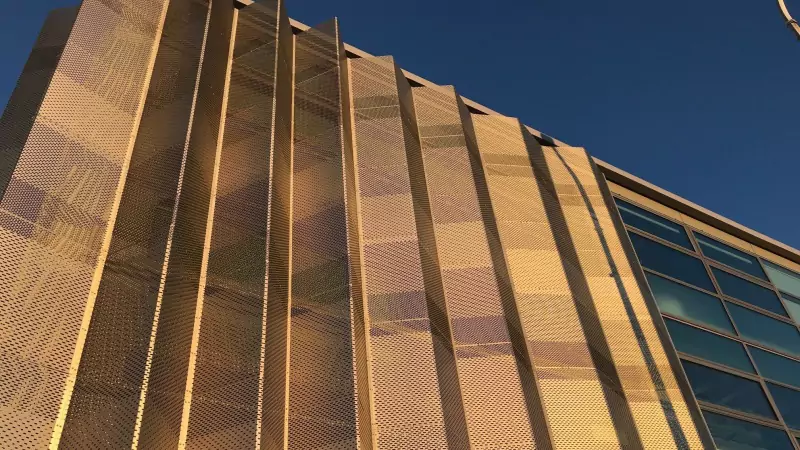

One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Rigorously tested to withstand 12-level typhoon simulations, the panels feature a secure edge-locking design to ensure stability in high-wind areas.

Advantage

A PVDF coating technology ensures that rainwater naturally cleans the surface, reducing the need for frequent maintenance and minimizing risks associated with high-altitude cleaning.

Just leave us your demand in 5 seconds and Xtrametal professional team will take care of your project from A TO Z

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Control open – area ratio and reinforce edges.

– Steps:

1. Limit perforation density to ≤30% for 3mm sheets

2. Add 20mm unperforated borders on all edges

3. Use CNC punching to maintain consistent hole spacing

– **Critical Note:** Avoid staggered hole patterns on panels >2m length to minimize thermal stress.

Maintain 8 – 12mm gaps between panels.

– Calculation Basis:

Formula: Gap = (ΔT × L × α) / 2

Where ΔT = 80°C (max), L = panel length, α = 23×10⁻⁶/°C (aluminum)

– Installation Tip: Use silicone – filled EPDM gaskets at joints for waterproofing without restricting movement.

No – post – coating bending cracks the finish.

– Process Flow:

1. CNC cutting → 2. Edge milling → 3. Press braking → 4. Surface treatment

– Alternative Solution: For complex shapes, use pre – coated aluminum coils (PE or PP films) with in – situ forming.

Minimum order quantity is 20㎡ (special processes start at 50㎡), with regular orders delivered within 15 working days. Complex

process orders do not exceed 25 working days (including a 7-day curing period).

We provide a 6063-T5 aluminum alloy keel system (load-bearing capacity ≥200kg/m²), with a matching hanging system that has

passed a 500,000-cycle fatigue test. Keel systems can be selected based on the installation method.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.