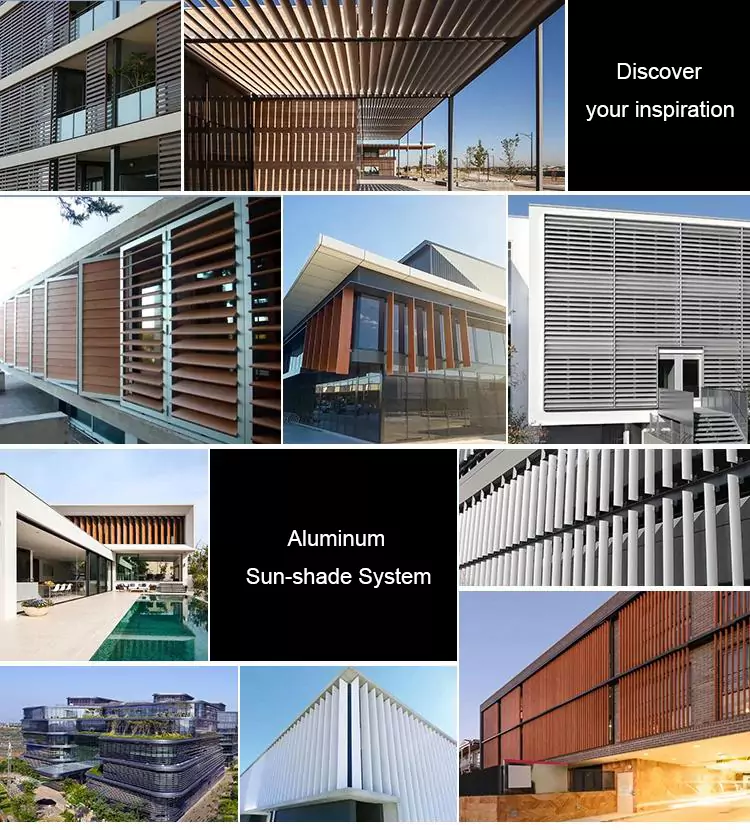

One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Advantage

Advantage

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

| Thickness | Application Scenario | Max Span (Unsupported) |

|———–|———————-|————————-|

| 1.5mm | Indoor decorative | 1.2m |

| 2.0mm | Low – rise exteriors | 1.8m |

| 3.0mm | High – wind regions | 2.5m |

Note: Always verify local wind codes and pair with reinforced mounting brackets for spans exceeding 2m.

Yes, CNC punching allows **round, square, or pattern – based perforations** with 1mm minimum aperture accuracy.

Process Details: 1. Submit CAD files specifying hole diameter (3 – 30mm) and spacing.

2. Maintain 40% max open area ratio to preserve structural integrity.

3. Deburring and edge sealing are mandatory post – punching to prevent corrosion.

Warning: Avoid perforations near mounting points (<50mm) to prevent stress fractures.

Step – by – Step Solution: 1. **Calculate expansion gap**: Allow 2mm per meter (ΔT = 40°C).

2. **Slotted screw holes**: Use 6x20mm oval holes for M6 fasteners.

3. **Joint design**: Install neoprene spacers between adjacent panels.

Critical Factors: – Account for solar radiation – induced heat (add 15% buffer in coastal tropics). – Avoid rigid connections to concrete substrates; use sliding anchors.

Over the past five years, we’ve upgraded our facilities with advanced CNC and laser equipment, doubling our output to meet growing demand.

Yes, we provide real-time order tracking through a dedicated customer portal or direct updates from our sales team upon request.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.