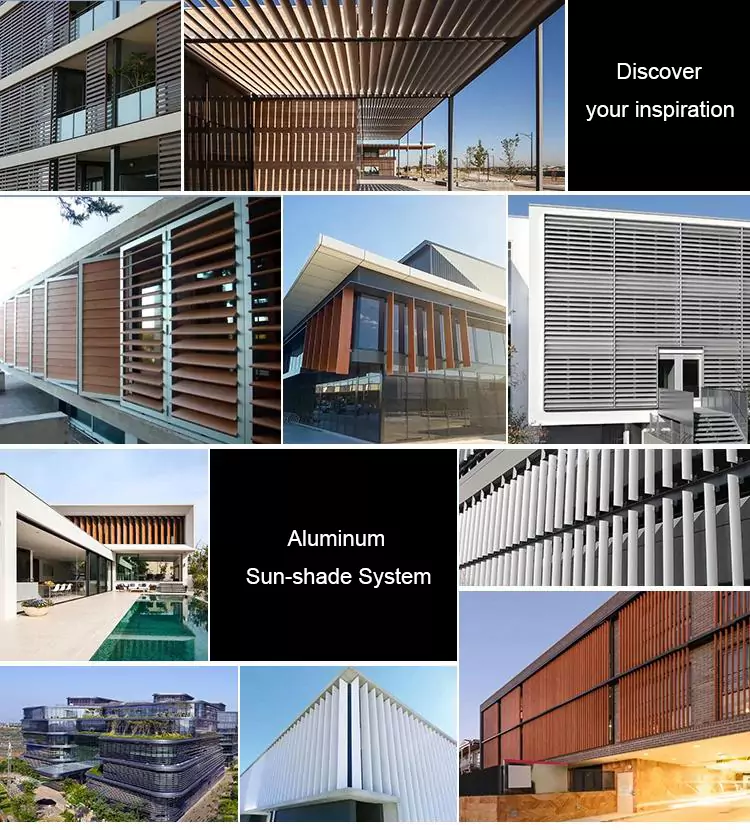

One-stop Solution for Residential & Commercial Building

Decoration Projects

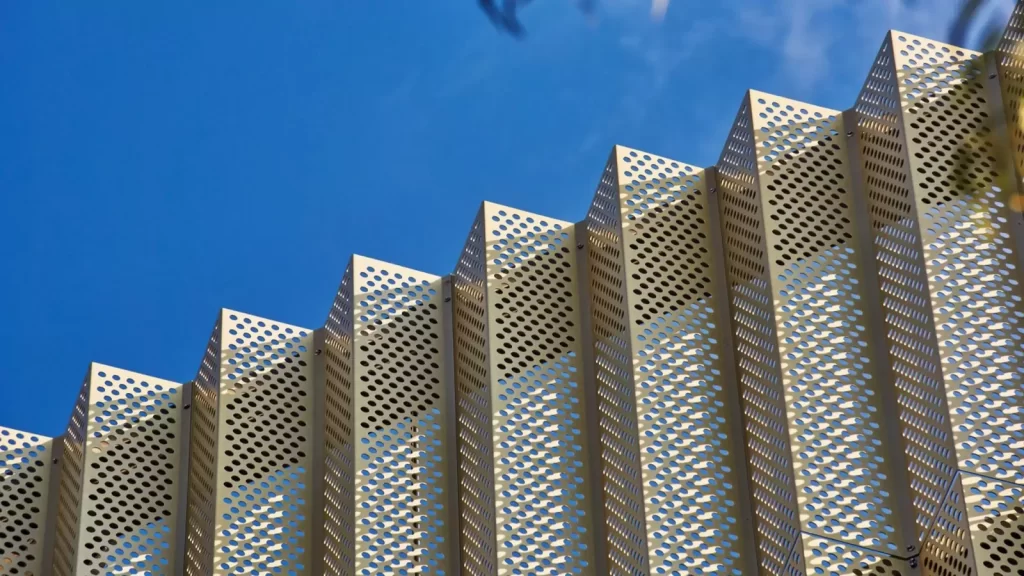

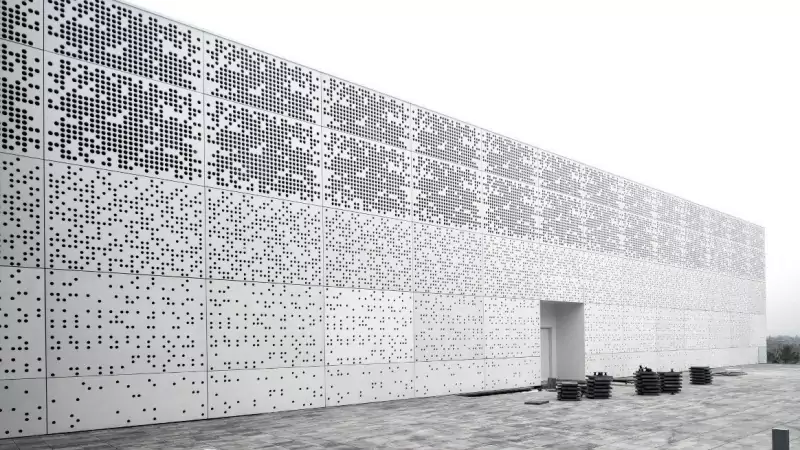

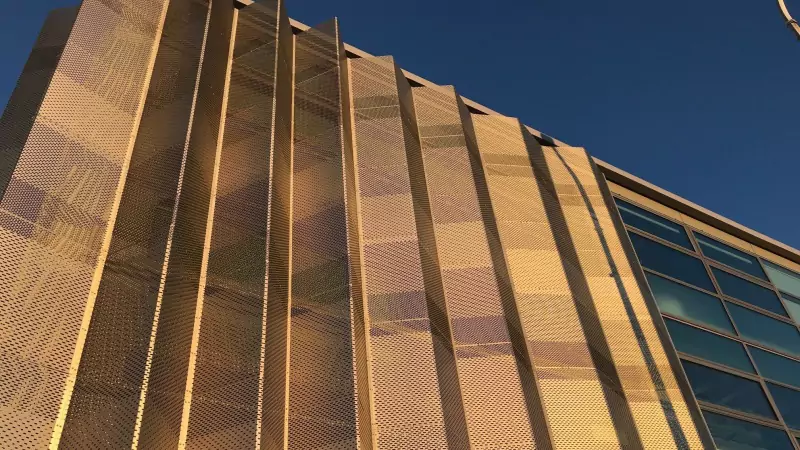

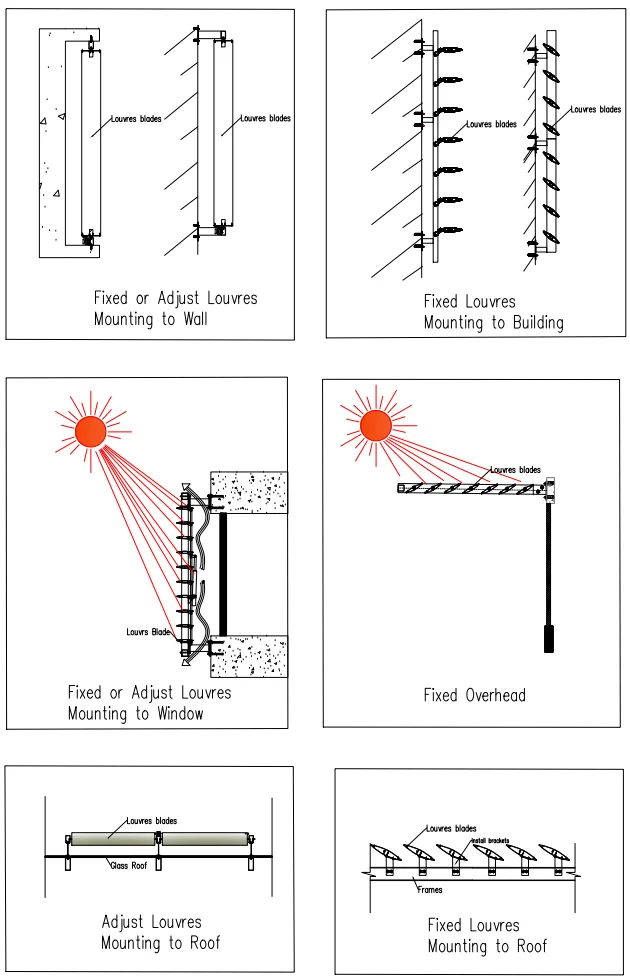

A louver facade is an exterior shading system composed of durable aluminum blades designed to optimize daylight control and airflow in buildings. Engineered for commercial and residential projects, its angled slats reduce solar heat gain while maintaining visual connectivity. Ideal for curtain walls and sunscreens, this low – maintenance solution combines weather resistance with sleek architectural expression.

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Advantage

Advantage

Rigorously tested to withstand 12-level typhoon simulations, the panels feature a secure edge-locking design to ensure stability in high-wind areas.

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Fluorocarbon coating and powder coating are optimal for aluminum louver facades, offering UV resistance and corrosion protection.

Technical Compatibility: BIM Parameters: Material: 2.5mm AA5005 with 0.7 – 1.2mm PVDF coating. Load capacity: 1.5kN/m² wind load (AS/NZS 1170.2 compliant). Interoperability: Compatible with Revit/MEP systems via IFC 4.0 format. Installation Tip: Specify 15mm adjustment tolerance in BIM models for on-site alignment.

### Comparison of key performances of aluminum alloys and selection recommendations

| Brand | Thermal conductivity (W/m·K) | Thermal expansion coefficient (μm/m·°C) | Characteristic mark |

|——–|——————-|———————–|———-|

| 1100 | 222 | 23.6 | ▲ |

| 3003 | 193 | 23.2 | — |

| 5052 | 138 | 23.8 | ● |

**Design Guide**:

– ● 5052 alloy: Recommended for coastal projects (magnesium content 2.2-2.8%, passed 4800 hours of neutral salt spray test)

– ▲ 1100 alloy: First choice for heat-sensitive scenarios (with 0.25W/m·K silicone insulation pad, system heat transfer coefficient ≤0.38)

– — 3003 alloy: general-purpose substrate (yield strength can be increased to 145MPa after cold working hardening)

**Technology extension**:

1. Corrosion resistance optimization: The surface of 5052 alloy adopts three-coating and two-baking process (in accordance with ASTM B209 standard), and has achieved a 12-year zero corrosion record in the Manila Bay project in the Philippines

2. Thermal deformation control: 1100 alloy + thermal insulation system was successfully applied to the Riyadh photovoltaic building integration project in Saudi Arabia (45℃ temperature difference between day and night)

3. Processing advantages: All grades support laser cutting (accuracy ±0.1mm) and CNC bending (R angle minimum 1.5t)

*Data source: GB/T 3190-2020 “Chemical Composition of Deformed Aluminum and Aluminum Alloys” / ASTM B209-14*

We enforce the GB/T 9286 color difference control standard, ensuring ΔE≤1.5 (visually no color difference). We offer a triple confirmation mechanism using Pantone color cards, RAL color systems, and physical samples, supporting sample retention.

We support EXW, FOB, and CIF price terms, with payment methods being a 30% advance payment and 70% balance settled before shipment.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.