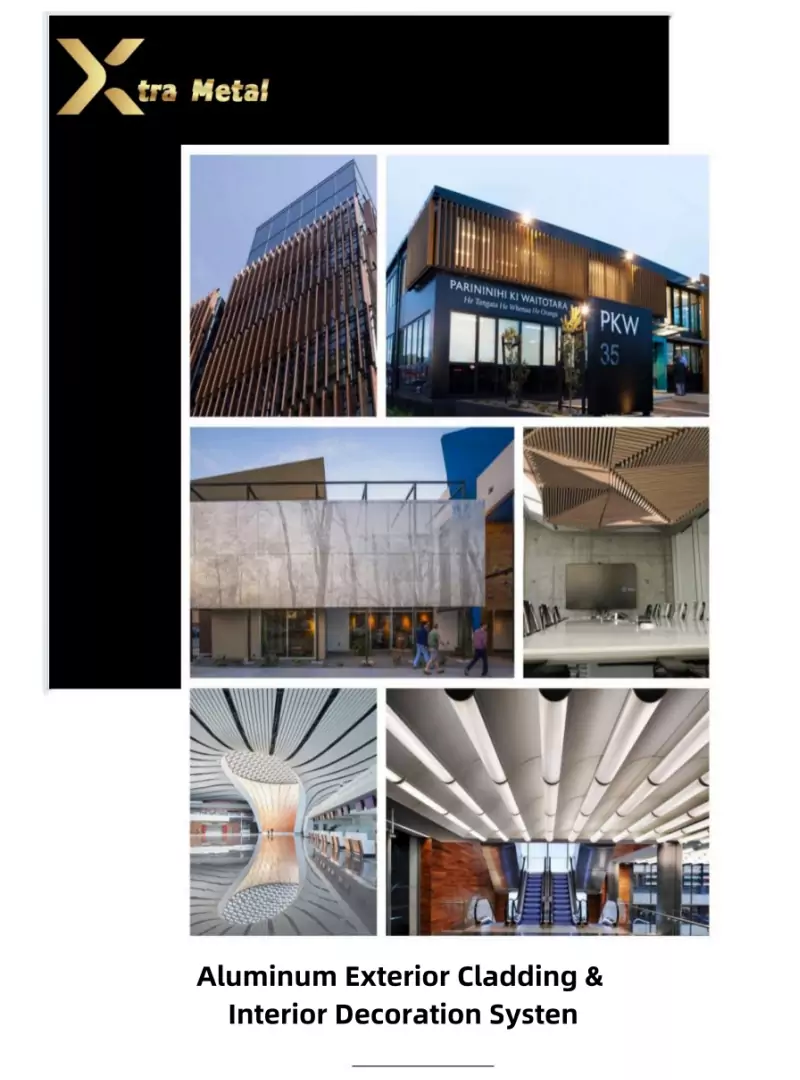

1. Introduction

Facade systems are engineered cladding solutions that form a building’s exterior envelope, serving structural, aesthetic, and functional roles. They integrate components like panels, insulation, substructures, and weatherproofing layers to protect against environmental stressors (Por exemplo, wind, moisture, thermal shifts) while enhancing architectural appeal.

2. Understanding Facade Systems

Components

Facade systems are made up of several parts that work together:

· Cladding: This is the outermost, visible layer. It can be made from a variety of materials, including metal panels, vidro, stone, wood, or composites.

(https://xtrametal.com/product/aluminum-cladding-exterior)

· Structural Supports: Metal or concrete elements that secure the cladding to the building’s frame.

· Insulation: Typically located behind the cladding, insulation is crucial for controlling the building’s internal temperature and enhancing its energy efficiency. Example: brown facade with thermal insulation for modern building applications.

· Glazing: Windows or glass panels that let in light while maintaining insulation.

Functions

These components serve multiple purposes:

·Aesthetic Appeal: Facades create a building’s unique style, from modern glass towers to classic brick designs.

·Weather Protection: They block rain, wind, and sun, protecting the structure and interiors.

·Thermal Insulation: Facades help control indoor temperatures, reducing energy costs.

·Acoustic Insulation: They reduce outside noise, improving occupant comfort.

·Energy Efficiency: By effectively managing heat transfer and light, facades are fundamental to improving a building’s overall energy efficiency.

3. Types of Facade Systems

There’s no single facade solution that fits every building. The choice of system depends on the building’s design, its intended use, budget, and performance requirements. Here are 8 common facade systems.

1. Curtain Wall Systems

Curtain wall systems are non-structural exterior walls, typically made of aluminum or glass. Painéis de parede externa de alumínio are commonly used in high-rise commercial buildings. They are designed to protect against the weather while allowing natural light into the building.

Advantages

· Aesthetic Appeal: Create a modern, sleek appearance with large glass panels, enhancing building visibility.

· Energy Efficiency: Can incorporate thermal breaks and insulated glass to reduce energy consumption.

· Leve: Reduce structural load, lowering foundation costs.

· Fire Safety: Act as fire stops between floors, improving safety.

· Weather Protection: Effectively block air and water infiltration.

· Structural Stability: Minimize building sway, enhancing overall stability.

Disadvantages

· High Cost: Expensive due to premium materials like glass and aluminum.

· Maintenance Needs: Requires regular sealant replacement every 10 anos.

· Installation Time: Stick-built systems can be time-consuming to assemble.

· Thermal Challenges: Poor design may increase solar heat gain, raising cooling costs.

2. Louver Facade Systems

Louvered facade systems incorporate adjustable slats into curtain walls to control light and ventilation, particularly effective in hot climates. There are many types of louver facades; the most common ones are vertical louver facades, horizontal louver facades, adjustable louver facades, etc..

Advantages

· Sun Control: Reduce solar heat gain and glare while allowing natural light.

· Ventilation: Enhance natural airflow, improving indoor air quality.

· Aesthetic Appeal: Create dynamic, visually engaging facades.

· Energy Efficiency: Lower cooling loads by providing shade.

· Privacy: Obstruct direct views without sacrificing light or airflow.

Disadvantages

· Cost: Custom designs can be expensive to engineer and install.

· Maintenance: Moving parts and slats require regular cleaning and upkeep.

· Design Complexity: Requires precise planning to optimize shading and ventilation.

3. Panel facade Systems

Panel facade systems, often unitized, consist of pre-assembled panels installed as units, streamlining construction for high-rise projects.

Advantages

· Faster Installation: Pre-fabrication reduces on-site construction time by up to one-third.

· Quality Control: Factory assembly ensures consistent quality.

· Reduced Labor: Minimizes the need for skilled on-site workers, lowering costs.

· Performance: Tighter tolerances improve air and water infiltration resistance.

Disadvantages

· Higher Initial Cost: Factory assembly and transportation increase expenses.

· Limited Flexibility: On-site modifications are challenging once panels are fabricated.

· Logistics: Large units require careful handling and transport.

4. Metal Facade Systems

Metal Facade System, primarily using aluminum or steel, emphasizes durability and modern aesthetics, aligning with Xtra Metal Group’s expertise in over 500 aluminum panel patterns.

Advantages

· Durability: Resistant to weather, fire, and pests, ensuring long-term performance.

· Low Maintenance: Minimal upkeep compared to materials like wood.

· Aesthetic Versatility: Offers various finishes, colors, and textures for customization.

· Leve: Reduces structural load, simplifying installation.

· Recyclability: Environmentally friendly due to recyclable materials.

Disadvantages

· Cost: Can be more expensive than alternatives like brick or vinyl.

· Thermal Conductivity: May require insulation to prevent heat transfer.

· Surface Damage: Susceptible to denting or scratching in some cases.

· Corrosion Risk: Certain metals may corrode in harsh environments without proper coatings.

5. Ventilated Facade Systems

Ventilated facade systems, similar to rainscreen cladding, use an air cavity to regulate temperature and moisture, enhancing building performance.

Advantages

· Energy Efficiency: Air cavity reduces heating and cooling costs by up to 30%.

· Moisture Control: Prevents condensation and mold, protecting the structure.

· Acoustic Insulation: Reduces external noise by up to 20%.

· Aesthetic Flexibility: Supports various cladding materials for design versatility.

· Durability: Shields the building from environmental damage.

Disadvantages

· Higher Initial Cost: More expensive than traditional facades due to complex design.

· Installation Complexity: Requires skilled labor for proper air cavity setup.

· Maintenance: Air cavity and cladding may need periodic checks.

6. Rainscreen Cladding Systems

Rainscreen cladding systems feature an outer layer with an air gap to manage moisture, ideal for humid climates. They protect the building structure while offering design flexibility.

Advantages

· Moisture Control: The air gap facilitates drainage and ventilation, preventing water infiltration.

· Energy Efficiency: Supports continuous insulation, reducing thermal bridges.

· Durability: Shields the building from weather damage, extending lifespan.

· Aesthetic Flexibility: Available in materials like aluminum, composites, or wood.

· Fire Safety: Some systems use fire-resistant materials, enhancing safety.

Disadvantages

· Cost: Higher initial costs due to complex design and materials.

· Installation Complexity: Requires precise installation to ensure effective air gap functionality.

· Maintenance: Periodic inspections are needed to maintain system performance.

7. Double-Skin Facade Systems

Double-skin curtain wall systems feature two layers, typically glass, with an air cavity for insulation, ideal for extreme climates.

Advantages

· Energy Efficiency: Reduces energy consumption through natural ventilation and thermal buffering.

· Acoustic Insulation: Enhances soundproofing for quieter interiors.

· Natural Ventilation: Improves indoor air quality with fresh air intake.

· Aesthetic Appeal: Offers transparency and design flexibility.

· Fire Safety: Can limit fire spread between floors.

Disadvantages

· High Cost: Expensive to design and construct due to dual layers.

· Maintenance: Cavity cleaning and upkeep increase operational costs.

· Space Usage: Cavity reduces usable floor space.

· Design Complexity: Requires careful engineering for optimal performance.

8. Green Facades

Green facades incorporate living plants, such as climbing vines or modular systems, to enhance sustainability and aesthetics.

Advantages

· Aesthetic Appeal: Create visually striking, natural building exteriors.

· Thermal Regulation: Insulate buildings, reducing energy costs.

· Air Quality: Plants absorb CO2 and pollutants, improving urban environments.

· Biodiversity: Support wildlife and urban ecosystems.

· Noise Reduction: Act as sound barriers, lowering noise pollution.

· Psychological Benefits: Enhance occupant well-being and reduce stress.

Disadvantages

· Maintenance: Require regular watering, pruning, and pest control.

· Initial Cost: High installation costs for irrigation and support systems.

· Structural Load: The Building must support the weight of plants and systems.

· Water Usage: Can increase water consumption in dry climates.

· Potential Damage: Roots or climbing mechanisms may harm the building if not managed.

The following table summarizes the key advantages and disadvantages of each facade system, aiding in project decision-making:

| Facade System | Key Advantages | Key Disadvantages |

| Curtain Wall Systems | Modern aesthetics, lightweight, energy-efficient | Energy efficiency, moisture control, and acoustic insulation |

| Rainscreen Cladding Systems | High cost, maintenance needs, and thermal issues | Costly, complex installation, maintenance |

| Panel Curtain Wall Systems | Instalação rápida, high quality, reduced labor | High cost, limited flexibility, and transportation challenges |

| Louvered Curtain Wall Systems | Sun control, ventilation, aesthetic appeal | Expensive, maintenance, design complexity |

| Metal Curtain Wall Systems | Durable, low maintenance, recyclable | Costly, thermal conductivity, corrosion risk |

| Ventilated Facade Systems | High cost, complex installation, and maintenance | Energy efficiency, acoustic insulation, and natural ventilation |

| Double-Skin Curtain Wall Systems | High cost, maintenance, space usage, and complexity | Aesthetic appeal, thermal regulation, and air quality improvement |

| Green Facades | Maintenance, high cost, structural load, water usage, and potential damage | Maintenance, high cost, structural load, water usage, potential damage |

4. Materials in Facade Systems

The choice of material is a cornerstone of facade design, influencing aesthetics, performance, durability, cost, and sustainability.

· Glass: Valued for its transparency, ability to maximize natural light, and sleek, modern appearance. It’s a fundamental component of curtain wall systems. Modern glazing technologies include multiple panes, low-emissivity (Low-E) coatings, and other treatments to enhance energy efficiency and control solar gain.

· Metals: Aluminum and steel are robust and versatile choices.

o Aluminum: It’s lightweight, strong for its weight, naturally resistant to corrosion, and highly recyclable. Aluminum can be easily shaped and is available in a vast range of finishes.

o Steel: Offers exceptional strength and can be used for both cladding and structural components. It typically requires protective coatings to prevent corrosion, especially in harsh environments.

· Stone and Brick: These traditional materials are renowned for their durability, timeless appeal, and excellent weather resistance. They can lend a sense of solidity and quality to a building.

Samples of glass, alumínio, and stone facade materials

· Wood: Provides a natural, warm aesthetic and can be a sustainable option if sourced responsibly from managed forests. However, wood generally requires more regular maintenance compared to other facade materials to protect it from moisture, insects, and UV degradation.

· Composites: These are engineered materials, often combining the beneficial properties of different substances. For example, Aluminum Composite Panels (ACPs) consist of two thin aluminum sheets bonded to a core material, offering a lightweight yet rigid solution. Fiber cement panels are another common composite, valued for their durability and versatility.

· Emerging Materials: The field is constantly innovating. We’re seeing exciting developments like:

o Photovoltaic Glass: Glass that can generate electricity from sunlight, playing a key role in energy-generating facades.

o ETFE (Ethylene Tetrafluoroethylene): A lightweight, highly transparent polymer film that can be used to create dramatic, often curved or inflated, facade structures.

5. Critical Design Considerations for Facade Systems

Designing a facade system is a complex undertaking that requires balancing numerous factors to achieve the desired aesthetic, performance, and longevity.

· Aesthetics and Architectural Expression: The facade defines the building’s visual identity. Material selection, cor, texture, form, proportion, and detailing all contribute to the architectural vision. The facade should align with the intended style and context of the building.

· Functionality and Performance:

o Weather Protection: The primary function is to shield the building from rain, wind, snow, and temperature extremes. This involves selecting appropriate materials and detailing for water-tightness and air permeability control.

o Thermal Performance: Managing heat gain and loss is critical for energy efficiency and occupant comfort. This involves insulation choice, minimizing thermal bridges, and considering solar orientation.

o Acoustic Performance: Controlling noise transmission from the exterior, especially in urban environments or near noise sources.

o Daylighting and Glare Control: Optimizing natural light penetration while managing glare and solar heat gain through glazing selection, shading devices (louvers, overhangs), and facade geometry.

· Structural Integrity: The facade system must safely resist all applied loads, including wind, seismic activity, and its own dead weight, and transfer these loads to the building’s primary structure. This includes the design of the substructure and connections.

· Energy Efficiency: A core consideration, driven by regulations and sustainability goals. This encompasses insulation levels (U-values), air tightness, solar heat gain coefficients (SHGC) of glazing, and the potential for passive design strategies. High-performance facades can significantly reduce heating and cooling expenses.

· Sustainability:

o Material Selection: Prioritizing materials with low embodied energy, high recycled content, local sourcing, and recyclability (Por exemplo, recycled aluminum, sustainably sourced wood).

o Lifecycle Impact: Considering the environmental impact from material extraction, manufacturing, transportation, operation (energy use, maintenance), and end-of-life disposal or recycling.

o Integration of Green Technologies: Incorporating elements like green walls, photovoltaic panels, or rainwater harvesting systems.

· Local Climate and Site Conditions: The facade design must respond to specific climatic conditions such as temperature ranges, humidity, solar exposure, wind patterns, and precipitation. For example, shading is crucial in hot climates, while maximizing solar gain is beneficial in cold climates. Site analysis should evaluate orientation, neighboring structures, and microclimate.

· Building Codes and Regulations: Compliance with local and national building codes is mandatory. These codes address structural safety, fire performance (Por exemplo, use of non-combustible materials, fire resistance ratings), energy efficiency, accessibility, and sometimes aesthetic guidelines.

· Maintenance Requirements and Durability:

o Material Durability: Selecting materials resistant to weathering, UV degradation, corrosion, and impact. For instance, stone and metal are generally durable, while wood may require more frequent upkeep.

o Accessibility for Cleaning and Repair: Complex facade designs may require specialized equipment for maintenance, adding to operational costs. Ease of cleaning and replacing components should be considered.

o Lifecycle: Designing for longevity to minimize the need for premature replacement.

· Cost (Initial and Lifecycle):

o Upfront Costs: Material costs, fabrication, installation labor, and equipment. Complex designs and high-performance materials typically have higher initial costs.

o Lifecycle Costs: Considering long-term operational expenses, including energy consumption, maintenance, repair, and eventual replacement. A higher initial investment in a durable, energy-efficient facade can lead to lower lifecycle costs.

· Constructability and Installation: The feasibility of building the designed facade, availability of skilled labor, and the complexity of the installation process are important practical considerations. Prefabrication can improve quality and speed, but requires careful planning for transportation and site fitting.

· Interfaces with Other Building Systems: Careful detailing is required at junctions with the roof, foundation, windows, doors, and structural penetrations to ensure continuity of weather barriers, insulation, and air barriers.

· Facade Access for Maintenance: For high-rise buildings, the design must incorporate or allow for facade access systems (Por exemplo, Building Maintenance Units – BMUs, gantries) for cleaning, inspection, and repair. The building structure, facade materials, cleaning cycles, and concealment of these systems are key design inputs.

6. Cost and Economic Aspects

The total cost of a facade system is influenced by a complex interplay of factors, ranging from initial material selection and design complexity to long-term operational and maintenance expenses. A comprehensive understanding of these cost drivers is essential for effective budgeting and decision-making.

Initial Costs: The upfront investment for a facade system can vary dramatically based on several factors:

· Materials Selected: High-performance glazing, natural stone, or custom-fabricated metal panels will generally have a higher initial cost than standard options like basic renders or simpler panel types.

· Design Complexity: Intricate geometries, non-standard panel sizes, and bespoke detailing will typically increase design, fabrication, and installation costs.

· System Type: More sophisticated systems, such as double-skin facades or highly customized curtain walls, will usually be more expensive than simpler panelized systems or EIFS.

· Installation Labor: The skill level required, the complexity of the installation process, site accessibility, and local labor rates all contribute significantly to installation costs.

Long-Term Savings: It’s vital to look beyond the initial purchase price. A well-designed, energy-efficient facade can lead to substantial long-term savings through:

· Reduced Energy Bills: Improved thermal insulation and solar control can significantly lower heating, ventilation, and air conditioning (HVAC) costs.

· Lower Maintenance Costs: Choosing durable, low-maintenance materials can reduce the frequency and expense of upkeep over the building’s lifespan.

· Increased Property Value: An attractive, high-performing, and well-maintained facade can enhance a building’s market value and appeal to tenants or buyers.

Cost Comparison: Table comparing costs across facade types. Providing exact figures is challenging as costs are highly project-specific. However, the following table offers a general relative comparison:

| Facade System Type | Relative Initial Cost | Relative Long-Term Maintenance | Potential Energy Savings | Key Cost Drivers |

| Standard Curtain Wall | Moderate to High | Moderate | Moderate to High | Type of glass, frame material (Por exemplo, alumínio), design complexity |

| Rainscreen/Ventilated | Moderate to High | Low to Moderate | High | Cladding material, cavity design, insulation type |

| Panel Facades (Aluminum) | Moderate | Low | Moderate | Panel finish, thickness, level of customization, aluminum grade |

| EIFS (Synthetic Stucco) | Low to Moderate | Moderate | Good | Quality of installation, type of finish coat |

| Traditional Brick/Stone | High | Very Low | Moderate | Quality of material, labor intensity for installation |

| Double-Skin Facade | Very High | Moderate to High | Very High | System complexity, types of glazing, and integrated controls |

| Green Facade | Moderate to High | Moderate to High | Moderate | Plant species, irrigation system, and structural support |

7. Maintenance and Durability of Facade Systems

The long-term performance and appearance of a building’s facade depend heavily on its inherent durability and a consistent maintenance regime. Neglecting these aspects can lead to premature deterioration, costly repairs, and a decline in property value.

· Routine Cleaning: Regular cleaning is essential to remove dirt, pollutants, biological growth (algae, moss), and stains, maintaining the facade’s aesthetic appeal and preventing material degradation. The cleaning method and frequency depend on the facade material, environmental conditions, and level of exposure. Glass facades, for example, may require frequent cleaning, though specialized coatings can reduce this need. Materials like ULMA’s engineered stone are noted for easy cleaning with soap and water.

· Regular Inspections: Periodic visual inspections should be conducted to identify any early signs of damage, deterioration, or failure. This includes checking for cracks, loose components, sealant failure, water staining, corrosion, and issues at joints and interfaces. Early detection can prevent minor problems from escalating into major, costly repairs.

· Sealant and Gasket Maintenance: Sealants and gaskets have a finite lifespan and can degrade due to weathering, UV exposure, and movement. Regular inspection and timely replacement of failed sealants are crucial to prevent water ingress and maintain air tightness.

· Repair of Damage: Prompt repair of any physical damage (Por exemplo, cracked panels, broken glass, dented metal) is necessary to maintain the facade’s integrity and weather resistance.

· Material-Specific Lifespan and Durability:

o Stone and Brick: Highly durable and can last for decades, even centuries, with minimal maintenance beyond occasional repointing of mortar joints for brick.

o Metal (Aluminum, Steel): Generally durable and low-maintenance. Aluminum is corrosion-resistant. Steel may require protective coatings (Por exemplo, galvanizing, painting) to prevent rust, especially in harsh environments. Recycled aluminum and thermally broken systems can enhance sustainability.

o Glass: High-quality tempered or laminated glass is strong and resistant to impact and weather. The lifespan of insulating glass units (IGUs) can be affected by seal failure.

o Wood: Requires regular maintenance, including cleaning, sealing, staining, or painting, to protect against moisture, decay, insects, and UV degradation. Lifespan depends heavily on the wood species, treatment, and maintenance regime.

o Fiber Cement: Very durable, resistant to diverse weather conditions, fire, and pests, requiring little maintenance.

o EIFS and Stucco: Can be durable if properly installed and maintained. However, EIFS can be prone to impact damage, and both can crack. Moisture intrusion is a significant concern if the system is not detailed or installed correctly, or if barrier systems are compromised.

o Coatings and Finishes: The lifespan of paints and coatings varies depending on the type and exposure conditions. Periodic recoating may be necessary to maintain appearance and protective qualities.

· Common Issues and Deterioration:

o Water Infiltration: Can lead to structural damage, mold growth, and reduced insulation effectiveness. Often occurs at failed joints, seals, or improper flashing details.

o Material Degradation: Fading of colors, corrosion of metals, decay of wood, spalling of concrete or stone.

o Structural Issues: Loosening of fixings, panel displacement, cracking due to thermal movement or building settlement if insufficient movement joints are provided.

o Thermal Bridging: Compromising insulation effectiveness and potentially leading to condensation.

· Impact of Design on Maintenance: The complexity of the facade design can significantly impact the ease and cost of maintenance. Facades with intricate details, difficult-to-access areas, or materials requiring specialized cleaning techniques will generally incur higher maintenance costs.

· Facade Access Systems: For multi-story buildings, adequate provision for facade access (Por exemplo, BMUs, davits, rope access points) is essential for safe and efficient cleaning and maintenance. This should be considered during the initial design phase.

8. FAQ Section

What’s the difference between a curtain wall and a rainscreen system?

Curtain walls are non-structural, often glass, and attach directly to the building frame. Rainscreens have an air gap to manage moisture, using materials like aluminum.

How do I choose the right facade material?

Look at climate, budget, and maintenance needs. Aluminum is durable and low-maintenance, while glass suits modern aesthetics but requires cleaning.

What maintenance do metal facades need?

Aluminum facades need periodic corrosion checks and cleaning, especially in coastal areas. Regular care extends their lifespan.

9. Conclusion

At Xtra Metal Group, we specialize in high-performance aluminum facade systems, leveraging 30+ years of expertise in precision engineering and global project delivery. Our solutions combine customizable material grades, advanced coatings, and modular designs—supported by full-spectrum technical guidance—to meet exacting standards for commercial and luxury residential applications.