One-stop Solution for Residential & Commercial Building

Decoration Projects

Advantage

Featuring a snap-together design, the panels enable quick and efficient installation, reducing labor costs and construction time by up to 50%.

Advantage

Advantage

Please send us a detailed inquiry and drawing. Include specifics such as size, layout, dimensions, color, material, and finish that you want for your project.

We will quote for you within 24 hours ! We have 400+ sale teams in designing and manufacturing for you .

After sending us your design and specifics, our sales team and engineers will offer 2-3 product solutions depending on your design and budget, subject to final approval.

As soon as you approves, a contract shall be signed. From here, the customization and manufacturing process begin.And our sales people would send you pictures of the production process and the finished product.

When your order completed and was packed, we would organize to load containers and shipping to your port .Even delivery to your warehouse.

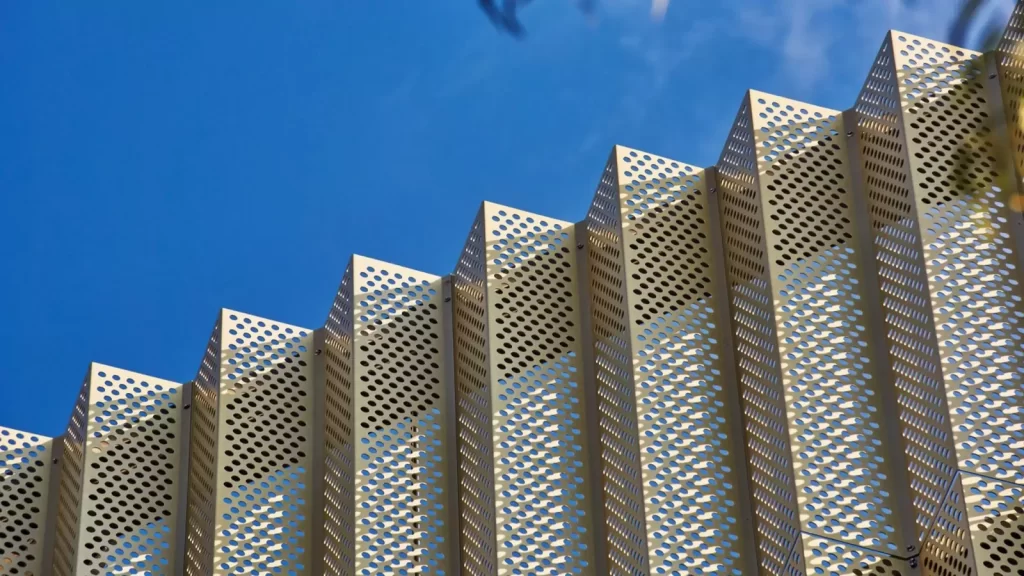

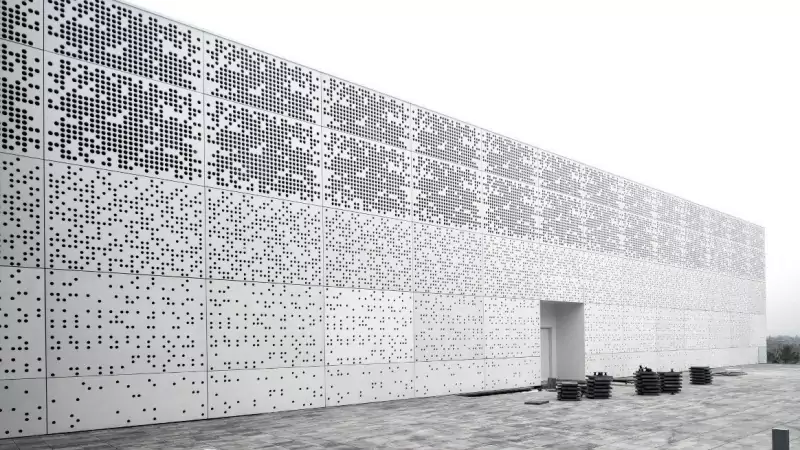

Xtrametal modular building project engineering showcase

XtraMetal has been in metal product manufacturing for 32 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Laser cutting ensures ±0.1mm precision, enabling complex geometric patterns and consistent hole alignment. It has the following aspects:

– Precision: Ideal for intricate designs (e.g., hexagonal arrays or custom logos) with repeatable accuracy.

– Edge Quality: Minimizes burrs, reducing post – processing needs.

– Material Integrity: Non – contact process preserves coating integrity (e.g., pre – coated PVDF panels).

Applications: Architectural façades requiring airflow + aesthetics, industrial filters needing <1mm tolerance.

Open area ratio (30 – 60% recommended) and hole spacing (≥2x hole diameter) determine load capacity.

Critical Parameters:

1. Pattern Type: Linear arrays weaken less than staggered layouts.

2. Material Thickness: 2 – 6mm aluminum (AA3003/AA5052) balances rigidity and weight.

3. Edge Reinforcement: Hemmed edges prevent tearing in wind loads >1.5kPa.

Testing: Always validate via FEM analysis for projects exceeding 3m panel length.

Maintenance Protocol:

1. Cleaning: Use soft – bristle brushes to avoid scratching anodized/painted surfaces.

2. Corrosion Check: Focus on joints and cut edges in high – humidity zones.

3. Coating Repair: Touch up scratches >2mm depth with OEM – matched paints.

Avoid: High – pressure washing (>80 psi) and acidic cleaners (pH <5).

All of our aluminum plate products strictly adhere to the national standard GB/T 23443-2009 “Aluminum Single Panels for

Architectural Decoration”, ensuring key performance indicators such as tensile strength ≥150MPa and coating thickness ≥25μm meet

the requirements.

Compared to stone, aluminum can reduce comprehensive costs by 40%-60%, with a unit weight of only 8-12kg/m² (stone ≥30kg/m²).

Compared to glass curtain walls, it enhances wind pressure resistance by 1.2 times, and maintenance costs are reduced by 70%.

Our team will be happy to respond to you in less than 24 hours.

*Your information will be kept strictly confidential.

One-stop Solution for Residential & Commercial Building Projects

Copyright © 2025 XtraMetal- All Rights Reserved

For any requirement, our team will be happy to respond to you in less than 24 hours.

Please provide us with your project design drawings, our professional designer team will evaluate your project and give professional suggestions within 24 hours。

Please provide us with your project requirements or bidding documents. Our professional team of designers will evaluate your project and give professional suggestions within 24 hours.

Tell us what product design you are interested in, and let’s streamline your design process – Get expert support instantly.