Aluminium cladding installation involves precision steps:

- Surface Preparation: Ensure substrate flatness and weatherproofing per Xtra Metal’s engineering specifications.

- Subframe Assembly: Install corrosion-resistant aluminum or steel rails, adjusted for structural integrity and thermal expansion.

- Panel Fixing: Secure pre-engineered panels (hal., cassettes, louvers) using concealed clips or rivets, maintaining consistent joint alignment.

- Sealing & Finishing: Apply specialized sealants at joints; integrate flashings for water management.

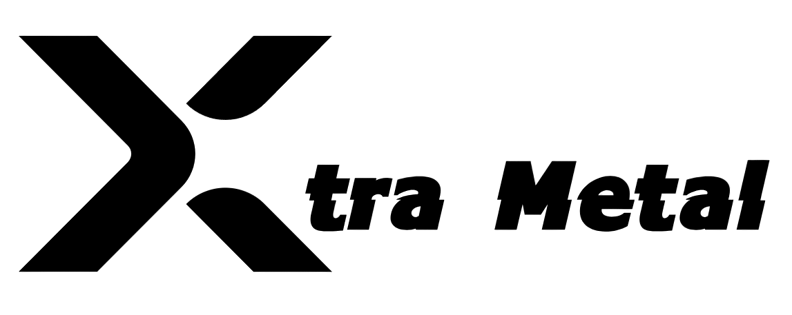

Xtra Metal Group optimizes installations via custom-designed systems tailored to architectural geometries, backed by 30+ years of global project expertise. Our ISO-certified workflows ensure seamless integration with complementary components (hal., insulation, ventilation), delivering durable, aesthetically flawless facades. Strict quality control guarantees compliance with international wind load and fire safety standards.